How To Design Your Custom Medals?

This article describes how tournament vendors can customise medals: 1. Determine the type of competition; 2. Determine the shape of

Half of the people are unsure of what to do when customizing a badge for the first time, as evidenced by facts:

“I don’t have experience, but I wanna start my business on it, and I lack the knowledge in this industry, can you help me to custom my club pin step by step?”

“I only have a design concept now. Can I customize it?”

“I have design drawings, but I don’t know which process is suitable for my design”

“Where to buy custom lapel pins?”

……

Don’t worry, now we have launched the ultimate guide to customizing lapel pins, which will help you to get an in-depth understanding of the industry and help you customize your lapel pin.

And since there are many similar names for lapel pins, we will use the lapel pin below to make the reading smooth.

The Steps For Custom Lapel Pins

1. Create Your Lapel Pin Design Sketch

2. Determine The Craft Of Lapel Pins

3. Choose The Size Of The Lapel Pin

4. Select The Pin Accessories

5. Choose The Packaging

6. Choose The Right Lapel Pin Manufacturer

7. Determine Budget

8. The Production Cycle Of Lapel Pin

If you want to create collectibles, and promotional items, show your creativity, or expand your brand, there is no doubt that making your unique lapel pin is the best.

1. Create your artwork design using professional design software, such as Adobe Illustrator, Photoshop, or CDR

2. Use free online design tools such as Canva, FotoJet, and Desygner…..

Owning and implementing your design, turning it from data form to physical form, and finally getting your hands on it is definitely exciting, but there are still a lot of design points to pay attention to before you get excited, we have put together the following points for you with over 10 years of experience:

1. Keep your design simple

2. Use clean and concise lines to ensure that the mold maker can directly understand, and do not need to spend your extra time to confirm

3. It is recommended to avoid the use of extremely complex external shapes and gaps

4. Avoid shadows in your artwork

5. Ensure that the color matches the Pantone color number

6. Decide the final weight of the lapel pins

Enlist the help of a graphic designer

If you are an artist with an idea but don’t have the time or experience to create these artworks, you can also seek the help of a professional graphic designer.

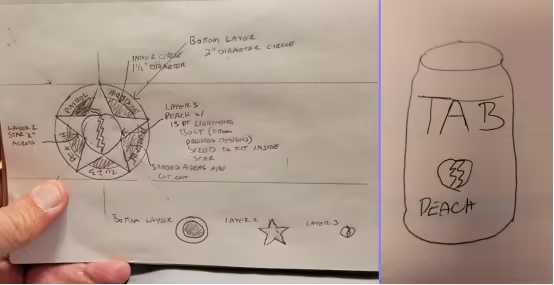

If your budget is limited, we provide free art design, you only need to provide your ideas, no matter the graphic work, sketch, or text description of the idea, our designers could help you to turn your ideas into reality, the style will be left to you to confirm, you can work with the designer to adjust your art bit by bit. Until the concept is exactly what you want.

If your budget is limited, we provide free art design, you only need to provide your ideas, no matter the graphic work, sketch, or text description of the idea, our designers could help you to turn your ideas into reality, the style will be left to you to confirm, you can work with the designer to adjust your art bit by bit. Until the concept is exactly what you want.

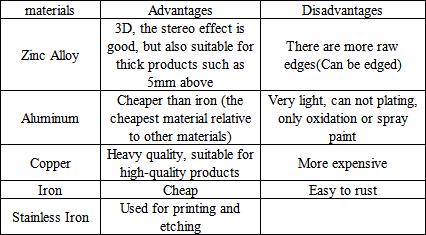

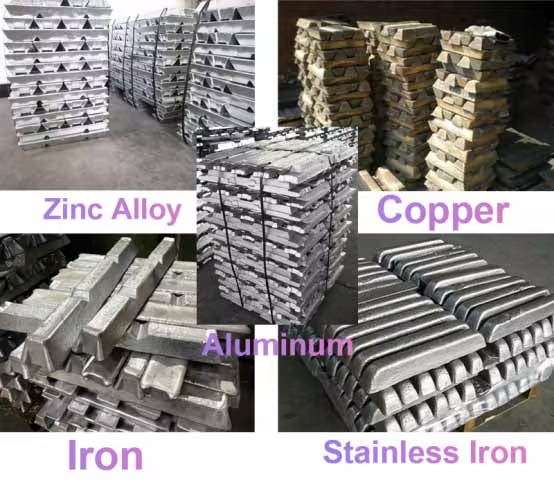

First of all, you need to select the product material you want.

Generally, there are mainly zinc alloys, aluminum, copper, iron, and stainless iron.

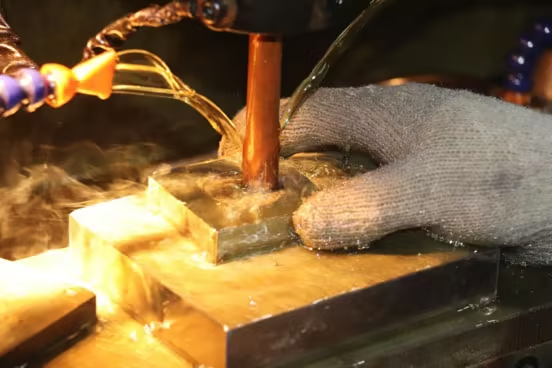

Zinc alloy material uses the die-casting process, and other materials used the die-stamping process.

Different materials productions have different textures, and the advantages and disadvantages of each material are different.

materials | Advantages | Disadvantages |

Zinc Alloy | 3D, the stereo effect is good, but also suitable for thick products such as 5mm above Low melting point and cheap | There are more raw edges(Can be edged) |

Aluminum | Cheaper than iron (the cheapest material relative to other materials) | Very light, can not plating, only oxidation or spray paint |

Copper | Heavy quality, suitable for high-quality products | More expensive |

Iron | Cheap | Easy to rust |

Stainless Iron | Used for printing and etching |

Next, you need to select what craft you want to use.

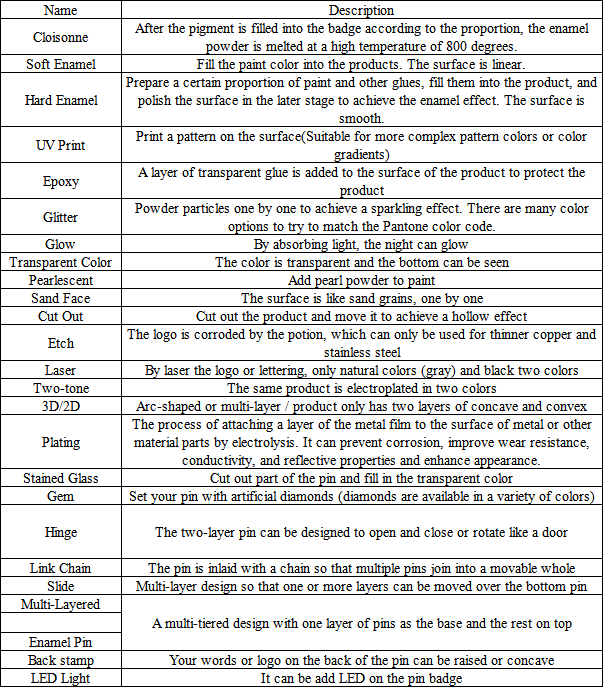

Name | Description |

Cloisonne | After the pigment is filled into the badge according to the proportion, the enamel powder is melted at a high temperature of 800 degrees. |

Soft Enamel | Fill the paint color into the products. The surface is linear. |

Hard Enamel | Prepare a certain proportion of paint and other glues, fill them into the product, and polish the surface in the later stage to achieve the enamel effect. The surface is smooth. |

UV Print | Print a pattern on the surface(Suitable for more complex pattern colors or color gradients) |

Epoxy | A layer of transparent glue is added to the surface of the product to protect the product |

Glitter | Powder particles one by one to achieve a sparkling effect. There are many color options to try to match the Pantone color code. |

Glow | By absorbing light, the night can glow |

Transparent Color | The color is transparent and the bottom can be seen |

Pearlescent | Add pearl powder to paint |

Sand Face | The surface is like sand grains, one by one |

Cut Out | Cut out the product and move it to achieve a hollow effect |

Etch | The logo is corroded by the potion, which can only be used for thinner copper and stainless steel |

Laser | By laser the logo or lettering, only natural colors (gray) and black two colors |

Two-tone | The same product is electroplated in two colors |

3D/2D | Arc-shaped or multi-layer / product only has two layers of concave and convex |

Plating | The process of attaching a layer of the metal film to the surface of metal or other material parts by electrolysis. It can prevent corrosion, improve wear resistance, conductivity, and reflective properties and enhance appearance. |

Stained Glass | Cut out part of the pin and fill in the transparent color |

Gem | Set your pin with artificial diamonds (diamonds are available in a variety of colors) |

Hinge | The two-layer pin can be designed to open and close or rotate like a door

|

Link Chain | The pin is inlaid with a chain so that multiple pins join into a movable whole |

Slide | Multi-layer design so that one or more layers can be moved over the bottom pin |

Multi-Layered Enamel Pin | A multi-tiered design with one layer of pins as the base and the rest on top |

Back stamp | Your words or logo on the back of the pin can be raised or concave |

LED Light | It can be add LED on the pin badge |

Every material and craft has a different effect on your artwork, and of course, their prices are also different.

So many crafts are sure to make your artwork to be the most ideal lapel pin.

At this point, you have completed a large part of your design.

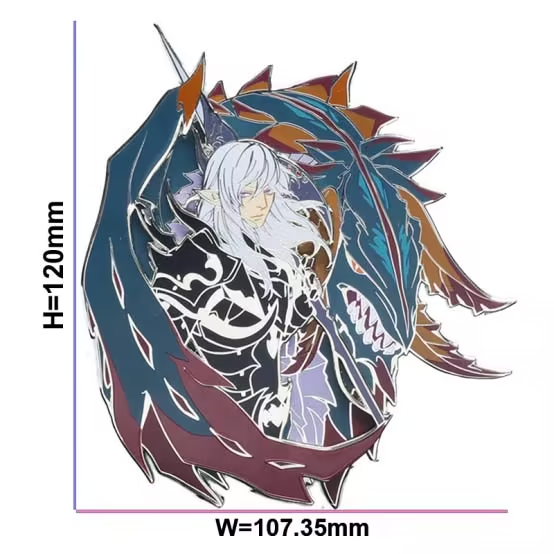

In this part, you need to determine the size and thickness of your artwork.

These are all related to cost. Then what size fits your design?

Large Badge

Generally, custom a larger pin badge is more than 3 inches. A larger size could better show the details of your design, but a larger size also limits where they can be worn. normally the larger one is more likely to be collected.

Pins(3”- 5”) feature:

1. It is suitable for high-detail requirements.

2. The artwork is full of details.

3. There are large animals, etc.

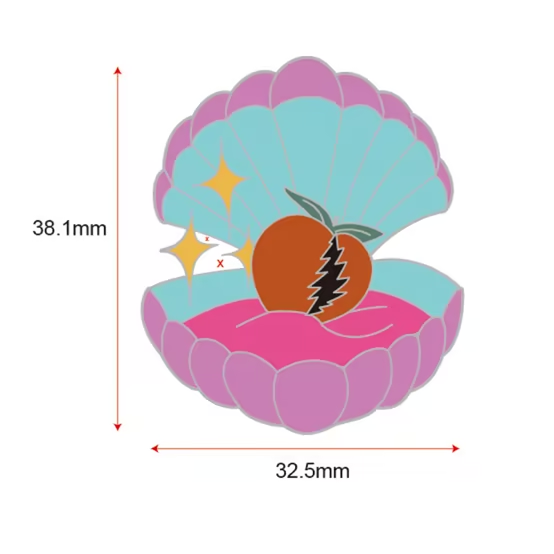

Small Badge

Custom small pins usually measure 0.5″ – 1.5″ wide or long. They’re lighter, easier to put anywhere, and cost less since they use less material. The downside of small pins is that they usually have less detail.

Pins(0.5” – 1.5”) feature:

1. Suitable for a few detailed, relatively simple design

2. School or company badge pins with less font

3. Event name or promotional product pin

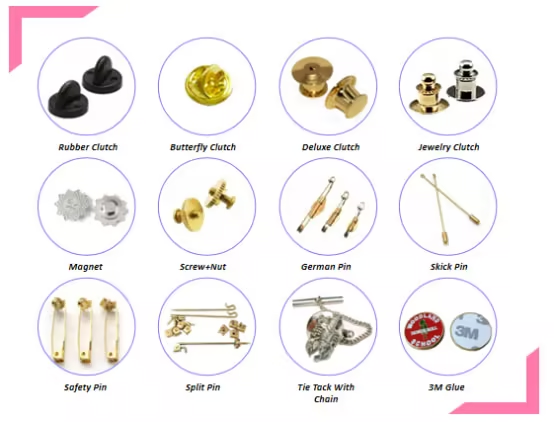

The back and the front of the pin’ customs are equally important. It is essential to choose different accessories according to the target audience of the artwork.

Like underage children, they are more suitable for safety pins. We provide many types of accessories for you to choose from.

At the same time, to stabilize and make the pin firm, different specifications need to use different numbers of pins.

If it is small, we usually recommend 1 pin, but when your pinback is large enough, we will suggest you use 3-5 pins according to the art product size.

Most artists will make background cards for their pins to highlight the artwork and put more information on the card to expand the impact.

We provide a variety of packaging materials for you to choose from, if you want others, just tell us and we will try our best to find them for you. I believe this packaging will add highlights to your lapel pins.

If you plan to give or sell your lapel pins on grand occasions, such as conferences, high-end gifts, etc., you may need to choose packaging that highlights your artwork without looking cheap.

If you’re doing this as a regular giveaway, or promotional gift, or if you want it to hang up right away, you may prefer to keep it simple.

After preparing your design draft and requirements, the most important thing is to choose a suitable supplier. We have listed some information that you may need to confirm with the supplier:

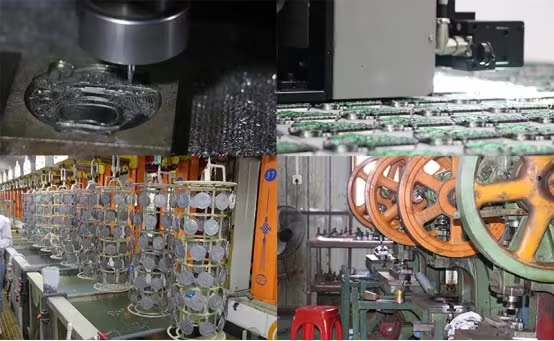

1. Rich experience

2. Timely communication

3. Is there a factory

4. Delivery period

5. Quality and return guarantee

6. What is the shipping method

7. Whether to accept expedited

8. What is the payment method

Once you have determined your partner, you can send your design draft, selected process, size, accessories, packaging, and quantity to the manufacturer partner.

The cost of customizing your lapel pins depends on your requirements and the first six steps because many manufacturer partners provide free design, so this cost can be ignored.

Other factors include:

Material/ Quantity/ Size/ Accessories/ Package/ Production Cost

Buying in large quantities could reduce costs for you, but if you want to buy in large quantities from a certain manufacturer, please place a small order first, so that you can determine whether this manufacturer’s products could meet your requirements.

After you are sure to trust this manufacturer, the large order can be completely handed over to the manufacturer for mass production.

If you have multiple designs in different channels or give customers multiple choices, you should ask the manufacturer to provide different packaging methods to match with lapel pins of different colors, which can highlight the characteristics of your artwork.

Usually, lapel pin manufacturers will keep your mold for three years, during this period, you don’t need to open the mold again to use this design, which will save you a lot of money, so choose one that will work with you for a long time, A trustworthy lapel pin manufacturer needs your careful consideration.

If you want to get a quotation for your artwork quickly, we recommend you to use the online quotation system or instant chat tool, which is often faster than an email reply, and you can also seek manufacturing through the online chat system for your various needs for design help from business partners.

When you complete the above steps, your design is very close to completion, you only need to pay a certain amount of advance payment (usually 20% or 30% of the entire order), and the manufacturer partner will start production when the manufacturer.

After the partner completes the production, they usually require you to pay the full amount. At this time, you must ask the manufacturer to take a video or photo for you to confirm whether the product quality meets the requirements.

After that, please confirm with the manufacturer the logistics method and customs clearance of the product.

It’s also worth mentioning that if you’ve set a certain time to start selling your product, make reservations at least 1-1.5 months in advance so your artwork arrives on time.

Generally speaking, it takes 1-4 weeks to complete your design for a general quantity of products.

If the quantity is large, you need to confirm the production time of your product with your manufacturer partner.

When the demand is in peak season, the production time may be shorter and longer.

Of course, the specific production time is subject to that provided by the manufacturer partner, and the time given in this guide is for reference only.

| Reference Time | |

| 100 – 500 | 7 days |

| 500 – 1000 | 12 days |

| 1000 – 5000 | 15 – 20 days |

| 10000 + | 20 days |

| DDP by sea | 30 – 35 days |

| DDP by air | 15 – 18 days |

| Express | 3 – 7 days |

| By road | 25 – 30 days |

| By railway | 25 – 30 days |

Well, these steps are the whole process of making your own lapel pin.

If you want to know more about lapel pins, you are welcome to contact us. If you have any questions, you are also very welcome to leave them in the comments. You can also contact me directly.

This article describes how tournament vendors can customise medals: 1. Determine the type of competition; 2. Determine the shape of

This article describes the 20 best promotional products for 2024

No. 5, Tongan Road,

East District Xiaolan Town,

Zhongshan, Guangdong,

China

Copyright © 2024, Zhongshan Peakeen Gifts Supply Chain Co., Ltd. All rights reserved. Powered by PeaKeen Privacy Policy

Let’s work together to achieve business growth!

10% Off