SWAT Team Pin: Meaning, Design, and Customization Guide

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

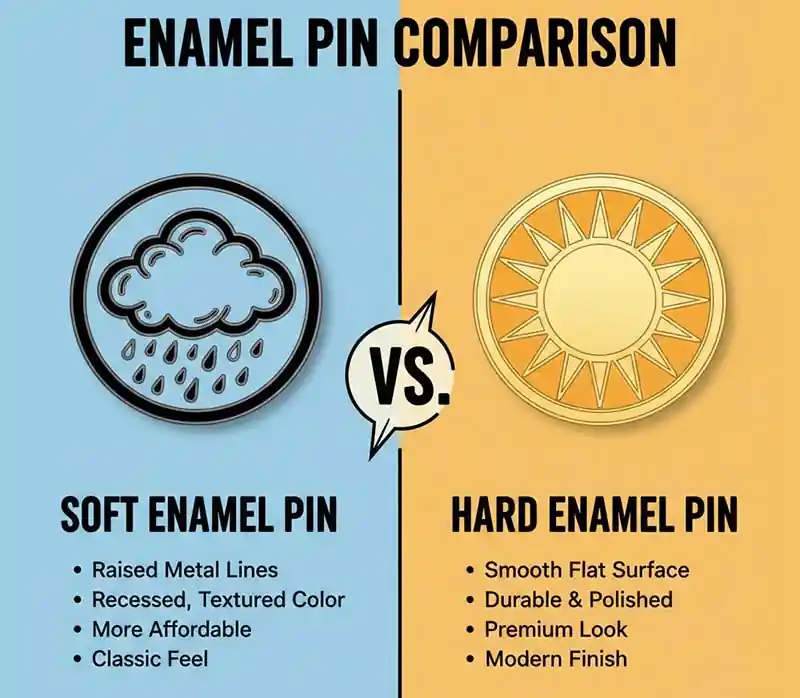

Choosing between soft and hard enamel pins can make or break your custom pin project. While both types start with the same metal base and use similar colored enamel materials, the finishing process creates dramatically different results in texture, appearance, cost, and durability.

For the short answer: soft enamel pins have a textured surface where the metal lines are raised above the enamel, while hard enamel pins are polished flat, resulting in a smooth finish.

Understanding the difference between soft vs hard enamel pins is crucial whether you’re creating merchandise for your brand, designing collector pins, or planning a promotional campaign. This comprehensive guide will walk you through everything you need to know to make the right choice for your specific project.

Enamel pins have become a staple accessory for expressing individuality, promoting brands, and commemorating special events. These small, eye-catching pins are crafted from a sturdy metal base and finished with colorful enamel, resulting in a durable and polished accessory that stands the test of time. Whether you’re looking to create a statement piece for your jacket, a collectible for your community, or a promotional item for your business, enamel pins offer endless possibilities.

There are two main types of enamel pins: soft enamel pins and hard enamel pins. The biggest difference between them lies in their finish and texture. Soft enamel pins are known for their raised metal edges and textured feel—when you run your finger across the surface, you’ll notice the enamel sits slightly lower than the metal lines, giving the pin a dimensional look. In contrast, hard enamel pins are polished flat, so the enamel and metal edges are at the same level, creating a smooth, glass-like surface. Both types are highly durable and can be customized to suit any design, but understanding the difference between soft and hard enamel is key to choosing the right pin for your needs.

The most fundamental distinction between soft and hard enamel pins lies in their surface texture and finish, not in the base materials used. When considering the difference between hard and soft enamel pins, both pin types begin with identical stamped metal molds and use the same colored enamel paints, but the production process creates entirely different end results.

Soft enamel pins feature raised metal borders with recessed colored areas. When you run your finger across a soft enamel pin, you can feel the distinct ridges where the metal lines rise above the colored enamel sections. This means enamel pins have raised metal edges, creating a textured, tactile surface that many collectors and designers appreciate for its dimensional quality.

Hard enamel pins have a completely smooth, polished surface where the metal lines and colored enamel sit at exactly the same level. The entire face of the pin feels flat and glassy to the touch, similar to high-quality jewelry or a watch face. This smooth finish gives hard enamel pins a premium, professional appearance that many associate with luxury accessories. The finished texture is a key factor: soft enamel pins have a ridged, textured feel, while hard enamel pins are smooth and flat.

The visual impact differs significantly between the two types. Soft enamel pins cast small shadows from their raised edges, creating depth and visual interest. Hard enamel pins reflect light evenly across their polished surface, producing vibrant, glossy colors that appear more saturated.

Both soft and hard enamel pins start with identical metal molds created through die stamping, where raised metal lines form borders and recessed areas hold the colored enamel. The key difference emerges during the filling and finishing stages of production. These differences highlight that soft and hard enamel are the main pin type options for those considering custom enamel pins.

Understanding the production process helps explain why soft vs hard enamel pins have such different characteristics and price points. While both types share the same initial manufacturing steps, their paths diverge significantly after the base preparation stage.

The common starting process involves converting artwork into a metal die that creates raised metal lines and recessed wells. The metal base (typically zinc alloy) is die-cast under high pressure, forming these raised and recessed areas. Brass and copper materials are produced using stamping processes. The raised sections become the metal borders visible in the final product, while the recessed areas hold the colored enamel.

After casting, the metal base is cut to its final shape and any attachment points like posts or clasps are soldered to the back. The pin then undergoes cleaning and preparation before the processes diverge into either soft or hard enamel production.

Soft enamel production follows a streamlined approach that prioritizes efficiency and design flexibility. The first major step involves metal plating, which happens before any enamel is added. This sequence allows for extensive plating options including gold, silver, nickel, black nickel, antique finishes, painted colors like matte black or white, and even rainbow anodized effects.

Once the metal plating is complete, liquid enamel paint gets carefully filled into the recessed areas. Crucially, the enamel is intentionally filled slightly below the level of the raised metal borders. This creates the signature texture where metal edges remain elevated above the colored sections.

The filled pin then goes into an oven for a single baking cycle at specific temperatures to cure and harden the enamel. During this baking process, the enamel loses some moisture and settles, which contributes to the final recessed appearance that defines soft enamel pins. Optionally, an epoxy coating can be applied to soft enamel pins after baking. This epoxy layer adds extra protection, increases weather resistance, and gives the pin a smooth finish similar to hard enamel.

The typical production timeline for soft enamel pins ranges from 10-14 days, making them the faster option for urgent orders.

Hard enamel production involves a more complex, multi-step process that creates the characteristic smooth, jewelry-like finish. Unlike soft enamel, the enamel colors are filled above the metal line level before the final plating stage, though some manufacturers may plate first depending on their specific workflow.

The process requires multiple baking cycles, with each color baked separately at high temperature to achieve maximum density and durability. A pin with five colors might require five separate baking sessions, each allowing the enamel to cure completely before the next color is added.

After all colors are filled and baked, the critical difference emerges: the entire surface undergoes grinding and polishing to create a perfectly flat surface. This process removes excess enamel until the colored areas sit flush with the metal lines, eliminating any texture or ridges. Due to the polishing process, hard enamel pins may have slightly less detail compared to soft enamel pins, as the metal lines can become thicker and some intricate design elements may be lost.

The grinding and polishing process requires significant labor and specialized equipment, contributing to both the higher cost and longer production timeline of hard enamel pins. The polished surface then receives final electroplating, resulting in a shiny, reflective finish.

Extended production timelines of 15-21 days are typical for hard enamel pins due to these extra manufacturing steps. The additional time and labor create a more expensive final product but result in superior durability and a premium appearance.

Soft enamel pins offer several compelling advantages that make them the preferred choice for many projects, particularly those with budget constraints or complex design requirements. Understanding these benefits helps determine when soft enamel is the optimal choice for your custom pins.

Cost-effectiveness stands as the primary advantage of soft enamel pins, typically running 15-25% less expensive than hard enamel equivalents. This price difference becomes more significant with larger orders, making soft enamel ideal for bulk merchandise, fundraising campaigns, and promotional giveaways where keeping per-unit costs low is essential.

Superior detail retention makes soft enamel pins excellent for complex artwork and fine lines. Intricate illustrations, detailed logos with small text, and complex geometric patterns maintain their clarity better with soft enamel than hard enamel, which can slightly soften fine details during the polishing process.

Unlimited plating color options represent another major advantage of soft enamel pins. Because plating happens before enamel filling and no grinding occurs, soft enamel supports any plating finish including matte black, antique effects, painted custom colors, and rainbow anodized finishes. These specialized platings are impossible with hard enamel due to the polishing requirements.

Faster turnaround times make soft enamel pins ideal for urgent orders or time-sensitive campaigns. The streamlined production process eliminates multiple baking cycles and grinding steps, allowing manufacturers to complete orders more quickly than hard enamel alternatives.

Soft enamel pins work particularly well for indie artists and small businesses creating merchandise, convention pins, enamel needle minders, and limited edition releases. The combination of lower costs, design flexibility, and faster production aligns perfectly with the needs of creators working with smaller budgets and tight deadlines.

The textured feel of soft enamel pins appeals to many collectors who appreciate the tactile quality and dimensional appearance. The raised metal edges create visual depth and interesting shadow effects that can enhance certain design styles, particularly those with strong line art or comic book aesthetics. When planning your next project, consider whether hard or soft enamel best fits your design, budget, and durability needs to ensure the best result.

Hard enamel pins command premium prices because they deliver superior quality, durability, and perceived value that justifies the additional cost for many applications. The advantages of hard enamel make it the preferred choice for projects where quality and longevity matter more than initial cost savings.

The premium appearance and perceived higher value of hard enamel pins make them ideal for corporate branding, awards, and luxury accessories. The smooth, glossy finish closely resembles fine jewelry or high-end watches, immediately communicating quality and sophistication to recipients and observers.

Enhanced durability and scratch resistance result from the multiple baking cycles and polished surface of hard enamel pins. The repeated high-temperature curing creates a denser, more robust enamel that resists scratching, chipping, and color fading better than soft enamel. This makes hard enamel pins suitable for frequent wear on clothing, bags, or lanyards where they’ll encounter regular friction.

The professional look of hard enamel pins makes them particularly suitable for corporate branding initiatives, executive gifts, and formal recognition programs. Companies often choose hard enamel for employee service awards, client appreciation gifts, and branded accessories because the finish aligns with professional image requirements.

Collector-quality finish makes hard enamel pins highly sought after for limited edition releases, commemorative items, and trading pin series. The premium feel and appearance justify higher retail prices, making them attractive for manufacturers targeting serious collectors willing to pay more for superior quality.

Hard enamel pins work exceptionally well for simple, bold designs where the smooth finish enhances color vibrancy and creates visual impact. Corporate logos, emblems, flags, and other designs with large color areas benefit from the even light reflection and saturated color appearance that hard enamel provides.

The long-term value proposition of hard enamel pins makes them cost-effective for items intended for extended use. While the initial price is higher, the superior durability means these pins maintain their appearance longer, providing better value over time for applications where pins will be worn regularly or displayed prominently.

Commemorative pins, award badges, and high-end retail accessories represent ideal applications for hard enamel pins where the premium finish justifies the additional cost and production time required.

Understanding the cost differences between soft and hard enamel pins helps budget planning and ensures you select the most cost-effective option for your project. Multiple factors contribute to pricing variations beyond the basic soft vs hard enamel choice.

Soft enamel pins typically cost 15-25% less than hard enamel equivalents, with the price difference increasing for larger orders due to the compounding effect of additional production complexity in hard enamel manufacturing. This percentage difference can translate to significant savings on bulk orders of 500+ pins.

The price difference increases with larger orders because hard enamel requires multiple baking cycles, grinding equipment operation, and skilled labor for polishing. Each of these steps adds both time and labor costs that compound with order size, making soft enamel increasingly attractive for high-volume projects.

Additional costs specific to hard enamel production include extra baking cycles for each color, specialized grinding equipment operation, polishing labor, and extended production time that ties up manufacturing capacity. These factors create the fundamental cost structure difference between the two pin types.

Custom plating options available only with soft enamel may offset the base cost advantage in some cases. Rainbow anodizing, painted finishes, and other specialty platings command premium pricing that can bring soft enamel costs closer to standard hard enamel pricing, though the soft enamel option still typically remains less expensive.

Pin Size | Soft Enamel (100 qty) | Hard Enamel (100 qty) | Price Difference |

|---|---|---|---|

1 inch | $2.50-$3.50 | $3.25-$4.75 | 20-25% |

1.25 inch | $3.00-$4.25 | $4.00-$5.75 | 25-30% |

1.5 inch | $3.75-$5.00 | $5.00-$7.25 | 30-35% |

These sample pricing ranges reflect common market rates for standard designs with 3-4 colors and basic gold or silver plating. Actual prices vary based on design complexity, color count, special features, and manufacturer selection.

Order quantity significantly impacts per-unit pricing for both pin types, with volume discounts typically ranging from 20-40% when comparing 100-piece orders to 1000+ piece orders. Hard enamel pins generally show steeper volume pricing curves due to the fixed costs of setup for grinding and polishing equipment.

When it comes to custom accessories, enamel pins stand out from alternatives like plastic or fabric pins due to their superior quality and resilience. Enamel pins are crafted from metal and finished with enamel, making them resistant to scratches, fading, and high temperatures. This durability ensures that your pins maintain their vibrant colors and polished appearance even with regular use.

Another advantage of enamel pins is their versatility in design and finish. They can be plated with a variety of metals, such as gold or silver, to achieve a luxurious, high-end look that plastic or fabric simply can’t match. The quality of enamel pins is evident in their weight, shine, and the crispness of their details, making them a preferred choice for anyone seeking a long-lasting and visually striking accessory. Whether you’re looking for a collectible, a promotional badge, or a fashion statement, enamel pins offer a premium solution that outperforms other materials in both appearance and durability.

Custom pins can be tailored to fit any vision, whether you prefer the dimensional look of soft enamel pins or the sleek finish of hard enamel pins. Soft enamel pins are a popular choice for those seeking a cost-effective option with plenty of design flexibility. Their raised metal edges, recessed areas, and vibrant colors allow for intricate artwork and a textured feel that stands out. This makes soft enamel ideal for bold, detailed designs and creative projects where tactile quality is a plus.

On the other hand, hard enamel pins are perfect for those who want a premium, polished surface that feels smooth to the touch. The hard enamel process creates a durable, high-quality pin that’s resistant to scratches and wear, making it suitable for frequent use or as a luxury accessory. The smooth, even finish of hard enamel pins is especially well-suited for intricate designs that require a refined, professional appearance.

When choosing between soft and hard enamel for your custom pins, consider your design, budget, and how the pins will be used. Soft enamel pins are generally more cost-effective and offer a unique, textured look, while hard enamel pins provide a sophisticated, durable finish. Both options allow you to create custom pins that reflect your style and meet your needs, ensuring your final product is both eye-catching and long-lasting.

The choice between soft and hard enamel significantly impacts how your design will appear in the final product. Understanding which designs work better with each finish type helps ensure your custom pins achieve the desired visual impact and maintain design integrity.

Most modern enamel pins do not use glass based enamels; instead, they rely on ceramic or epoxy-based materials for durability and finish.

Design complexity, line thickness, color arrangement, and intended aesthetic all influence which enamel type will produce the best results. Making the right choice early in the design process can mean the difference between a pin that perfectly captures your vision and one that loses important details or visual appeal.

Intricate artwork with fine details and thin lines benefits significantly from soft enamel production. Since no polishing process occurs, even the most delicate metal lines remain sharp and well-defined. Complex illustrations, detailed character art, and technical drawings maintain their precision better with soft enamel than hard enamel, which can round off sharp edges during the grinding process.

Designs requiring non-standard metal finishes like rainbow anodizing, matte black, or painted colors must use soft enamel since these specialized platings cannot survive the grinding and polishing required for hard enamel. This makes soft enamel essential for designs where the metal color plays a crucial role in the overall aesthetic.

Logos with small text or complex geometric patterns work better with soft enamel because the raised metal edges help define and separate design elements. The textured surface created by the recessed enamel and raised metal lines can enhance readability and visual separation between different parts of the design.

Vintage or distressed aesthetic designs benefit from the dimensional quality that soft enamel provides. The shadows cast by raised metal edges create depth and visual interest that complements retro styling, comic book aesthetics, and artistic designs where texture adds to the overall appeal.

Designs with many small, separate colored areas work well with soft enamel because the raised metal borders act as natural dividers that prevent colors from appearing to blend together. This makes soft enamel ideal for complex illustrations with numerous color transitions or detailed artwork adapted from other media.

Simple, bold designs with larger color areas showcase the advantages of hard enamel beautifully. The smooth, polished surface allows colors to appear more vibrant and saturated while the even light reflection creates a luxurious appearance that enhances minimalist or modern design aesthetics.

Corporate logos requiring a polished, professional appearance benefit from hard enamel’s jewelry-like finish. The smooth surface and consistent light reflection create an premium impression that aligns with professional branding requirements and corporate image standards.

Designs where durability is a priority over fine detail work better with hard enamel. The robust finish withstands wear and maintains color vibrancy longer than soft enamel, making it ideal for pins that will be worn frequently or displayed in high-traffic areas.

Classic designs that benefit from traditional gold or silver plating look exceptional in hard enamel. The polished metal borders complement the smooth enamel surface to create a cohesive, elegant appearance reminiscent of traditional cloisonné jewelry or fine accessories.

Flag designs, emblems, badges, and other symbolic imagery work particularly well with hard enamel because the smooth finish allows for crisp color blocks and clean lines. The premium appearance enhances the perceived importance and formality of official symbols and organizational imagery.

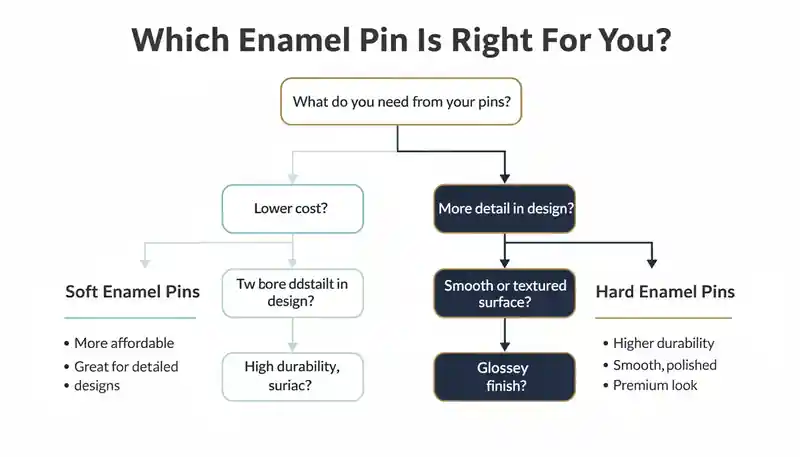

Making the right choice between soft and hard enamel requires evaluating several key factors that align with your project’s specific requirements, budget constraints, and target audience expectations. This decision framework helps ensure you select the optimal finish for your custom pins.

Budget considerations often drive the initial decision, with soft enamel offering the most cost-effective solution for projects with limited funding. If your budget allows for only soft enamel pricing, this choice is straightforward. However, if budget permits both options, evaluate the other factors to determine which provides better value for your specific application.

Timeline requirements may determine your choice when working with tight deadlines. Soft enamel’s faster production timeline of 10-14 days versus hard enamel’s 15-21 days can be crucial for time-sensitive campaigns, event merchandise, or last-minute promotional needs.

Target audience expectations significantly influence the appropriate choice. Hard enamel appeals to collectors willing to pay premium prices for superior quality, while soft enamel works well for broader audiences focused on design creativity and affordability. Corporate clients often expect the professional appearance that hard enamel provides.

Design complexity assessment helps determine which process will better preserve your artwork’s integrity. Highly detailed designs with thin lines, small text, or intricate patterns generally benefit from soft enamel’s detail preservation, while simple, bold designs may look better with hard enamel’s smooth finish.

Intended use patterns affect durability requirements. Pins for frequent wear, outdoor use, or high-handling situations benefit from hard enamel’s scratch resistance, while display pieces, trading pins, or occasional-wear items work fine with soft enamel’s durability level.

Consider these decision points in order of priority for your project:

Budget constraints: Does your budget allow for hard enamel pricing?

Timeline requirements: Do you need delivery within 10-14 days?

Design complexity: Does your artwork include fine details or thin lines?

Plating requirements: Do you need non-standard plating colors?

Target market: Are you serving collectors or general consumers?

Durability needs: Will pins experience frequent wear or handling?

Aesthetic preference: Do you prefer textured or smooth finishes?

If budget allows both options and timeline isn’t restrictive, prioritize design complexity and intended use to make your final decision. Complex designs generally work better with soft enamel, while simple designs and high-wear applications favor hard enamel.

For first-time pin creators uncertain about their choice, soft enamel provides a lower-risk option with design flexibility and cost savings that allow for learning and iteration. Experienced creators with established markets may choose hard enamel for its premium positioning and collector appeal.

The choice between soft vs hard enamel ultimately depends on balancing your project’s specific requirements, constraints, and goals. Both options can create excellent results when matched appropriately to their intended application and target audience.

Understanding the complete picture of differences, advantages, and considerations helps ensure your custom enamel pins achieve their intended impact while staying within budget and timeline requirements. Whether you choose the cost-effective flexibility of soft enamel or the premium durability of hard enamel, making an informed decision based on your project’s unique needs will result in pins that successfully serve their purpose and satisfy your target audience.

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

Table of Contents This guide covers everything you need to know about custom punk rock pin design, materials, and manufacturing.

No. 5, Tongan Road,

East District Xiaolan Town,

Zhongshan, Guangdong,

China

Copyright © 2024, Zhongshan Peakeen Gifts Supply Chain Co., Ltd. All rights reserved. Powered by PeaKeen Privacy Policy

Let’s work together to achieve business growth!