SWAT Team Pin: Meaning, Design, and Customization Guide

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

When it comes to creating challenge coins, there are countless materials and crafts to choose from. We’re talking about five or six different materials and over 10 crafts! We’ve got zinc alloy, brass, hard enamel crafts, 3D printing, and more.

Now, you might be wondering, which ones are the most common and suitable?

Well, fret not! We’ve got you covered. By using these tried-and-true materials and techniques, you can breathe easy and save yourself 80% of the worry.

Crafts: Zinc alloy (the ideal material) and brass (provides the best tactile experience).

Hard enamel (also known as imitation enamel) and soft enamel (used for enamel coating).

Still, have doubts about other materials and crafts? No problem, this article will start from the following dimensions:

1. Why should zinc alloy material be the most suitable?

2. Can I make a mirror effect?

3. Which process to choose for making gradient colors?

4. Can you make antique colors?

5. What are the other crafts?

6. What are the coin edges to choose from?

7. Do you have public templates?

Zinc alloy material is in a stable state and does not easily react with the outside world like iron.

The melting point of zinc alloy is relatively low, and it can be injected into the mold like water after melting, while the price of zinc alloy is lower than that of copper.

Our products can achieve a stunning mirror-like effect.

The mirror effect is just like a mirror, reflecting objects in front of the commemorative coin.

Creating this mirror effect is a true test of craftsmanship, requiring meticulous polishing by our skilled artisans:

① First, rough polishing is carried out to smooth the rough surface.

② Next, medium-level polishing is done to enhance the smoothness and glossiness of the coin’s surface.

Polishing wax is used, and the direction of medium polishing is at a slight angle compared to rough polishing.

③ Lastly, fine polishing is performed using the finest polishing wheel and ultra-fine white wax.

After polishing, the product surface is gently wiped with a soft cloth to ensure a perfect mirror-like effect.

Gradual color effects are typically achieved through UV printing. Our current skill set allows us to print colors directly onto the product surface, creating a seamless gradient effect.

On the other hand, screen printing is not commonly used for printing gradients due to higher costs and the risk of color bleeding.

If you’re interested in learning more about the differences between the two methods, please refer to this BLOG.

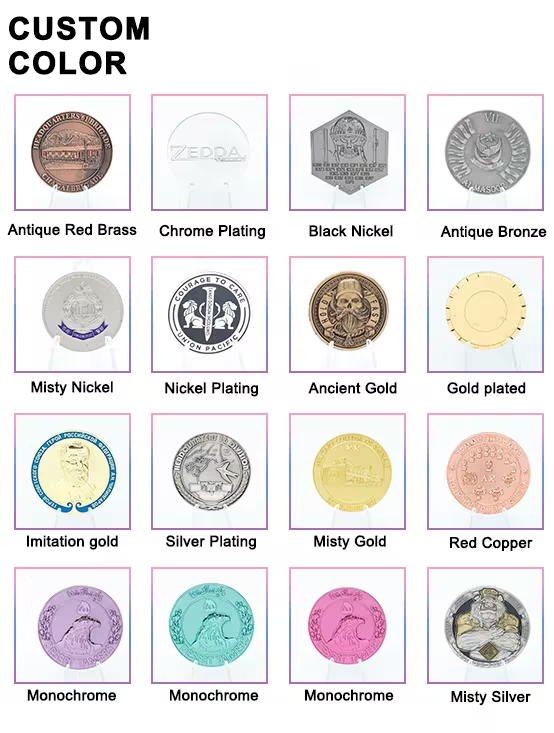

We specialize in creating antique colors, such as ancient bronze, ancient copper, antique gold, antique silver, and antique nickel.

These colors give your products a vintage feel, exuding a sense of elegance, and are perfect for diplomatic gifts, commemorative events, and more.

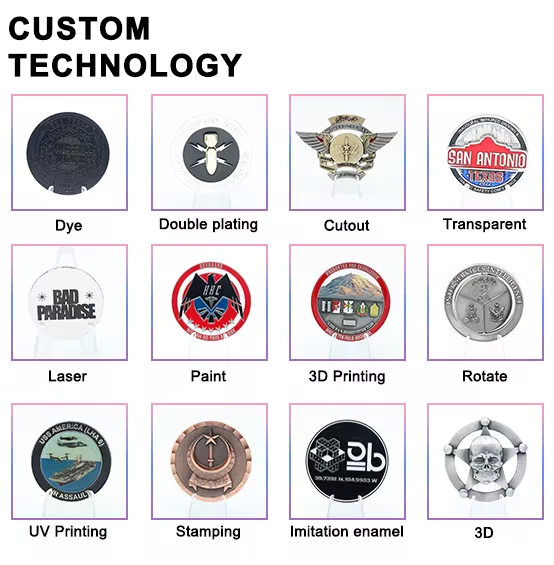

We offer a wide range of techniques for you to choose from, including diamond-cutting, hard enamel, gold plating, glow-in-the-dark paint, spin casting, 3D effects, dual plating, and more.

Some of these techniques can even be combined for a truly unique result. If you’re interested in using multiple techniques for your product, please contact us for consultation.

We provide various options for the edges of commemorative coins, such as rope, cross-cut, spur, bezel, and more.

If you don’t find the edge style you desire or if you have your own custom edge design in mind, please email us, and our international trade team will assist you in the design process.

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

Table of Contents This guide covers everything you need to know about custom punk rock pin design, materials, and manufacturing.

No. 5, Tongan Road,

East District Xiaolan Town,

Zhongshan, Guangdong,

China

Copyright © 2024, Zhongshan Peakeen Gifts Supply Chain Co., Ltd. All rights reserved. Powered by PeaKeen Privacy Policy

Let’s work together to achieve business growth!