SWAT-Team-Pin: Bedeutung, Design und Anpassungsleitfaden

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

Siebdruck und Thermosublimationsdruck sind die am häufigsten verwendeten Technologien für Bänder.

Der Siebdruck, der vor mehr als zweitausend Jahren in China entstand, ist eine traditionelle Drucktechnik, während der Farbsublimationsdruck eine moderne Technologie ist.

Obwohl es sich bei der Farbsublimation um eine moderne Technologie handelt, gibt es für den Siebdruck nach wie vor eine Vielzahl von Anwendungsmöglichkeiten.

Worin bestehen die Unterschiede zwischen den beiden, und was sind ihre jeweiligen Vor- und Nachteile?

Einige unserer Kunden haben diese Fragen, deshalb haben wir diesen Artikel geschrieben, um allen zu helfen, das Handwerk besser zu verstehen.

Die Kenntnis dieser beiden Technologien wird uns helfen, das richtige Band für unsere Auszeichnungen auszuwählen.

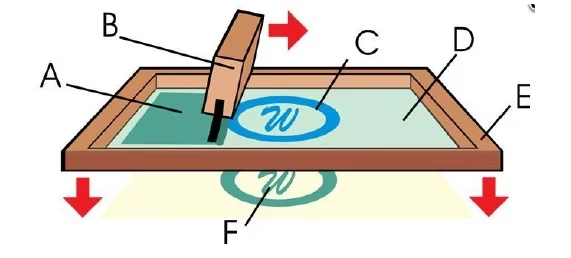

Siebdruck ist die Verwendung von Siebdruckplatte Grafiken Teil des Netzes durchlässig für Tinte, nicht-grafischen Teil des Netzes undurchlässig für Tinte das Grundprinzip des Druckens.

Drucken in der Siebdruckplatte an einem Ende der Farbe gegossen, mit einem Rakel auf der Siebdruckplatte Farbteile, um einen bestimmten Druck anzuwenden, während in Richtung des anderen Endes der Siebdruckplatte zu bewegen. Tinte in der Bewegung der Rakel aus dem grafischen Teil des Bildschirms Loch Extrusion auf dem Substrat. So wird das Muster auf dem Substrat fixiert.

Beim Thermosublimationsdruck wird Thermosublimationstinte auf Papier (oder Kunststofffolie) gedruckt. Anschließend wird das Papier (oder die Folie) mit der gedruckten Grafik über den Stoff gelegt, erhitzt und unter Druck gesetzt, und der Farbstoff auf dem Papier (oder der Folie) wird sublimiert und in der Gasphase auf den Stoff übertragen.

Siebdruck: Entwurf, Farbtrennung, Plattenherstellung, Farbfixierung, Lagerung von Siebdruckplatten, Fertigstellung. Thermosublimation: Entwurf, Druck von Transferpapier, Transferdruck, Speicherung im Computer, Fertigstellung.

Wir können leicht sehen, dass der Siebdruck ein Plattendruck ist, während das Merkmal der Thermosublimation darin besteht, dass keine Plattenherstellung erforderlich ist, was den Prozess und die Kosten der Plattenherstellung einspart, so dass es für die Herstellung von bedruckten personalisierten Produkten geeignet ist.

Aus der Sicht der Druckwirkung. Siebdruck aufgrund von "Farbe" und anderen Einschränkungen, kann nicht gedruckt werden, ähnlich wie Farbverläufe, Wolken und andere hochpräzise Muster, und Thermosublimationsdruck ist Tintenstrahldruck, so dass nicht vorbehaltlich der Farbe Einschränkungen, so von der Druckwirkung, können mehrere Farben, Farbverläufe drucken ist der wesentliche Unterschied zwischen den beiden.

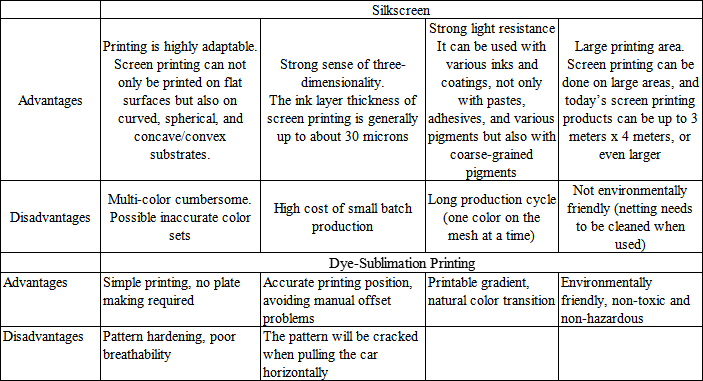

Siebdruck | ||||

Vorteile | Der Druck ist äußerst anpassungsfähig. Der Siebdruck kann nicht nur auf flache Oberflächen, sondern auch auf gewölbte, kugelförmige und konkave/konvexe Substrate gedruckt werden. | Starkes Gefühl der Dreidimensionalität. Die Farbschichtdicke beim Siebdruck beträgt im Allgemeinen bis zu 30 Mikrometer. | Starke Lichtbeständigkeit Es kann mit verschiedenen Druckfarben und Beschichtungen verwendet werden, nicht nur mit Pasten, Klebstoffen und verschiedenen Pigmenten, sondern auch mit grobkörnigen Pigmenten | Große Druckfläche. Der Siebdruck kann auf großen Flächen durchgeführt werden, und die heutigen Siebdruckprodukte können bis zu 3 m x 4 m oder noch größer sein. |

Benachteiligungen | Mehrfarbig ist umständlich. Mögliche ungenaue Farbsätze | Hohe Kosten der Kleinserienproduktion | Langer Produktionszyklus (jeweils eine Farbe auf dem Netz) | Nicht umweltfreundlich (das Netz muss nach Gebrauch gereinigt werden) |

Farbstoff-Sublimationsdruck | ||||

Vorteile | Einfacher Druck, keine Plattenherstellung erforderlich | Genaue Druckposition, Vermeidung von Problemen beim manuellen Versatz | Druckbare Farbverläufe, natürliche Farbübergänge | Umweltfreundlich, ungiftig und ungefährlich |

Benachteiligungen | Verhärtung des Musters, schlechte Atmungsaktivität | Das Muster wird beim horizontalen Ziehen des Wagens geknackt | ||

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

Table of Contents This guide covers everything you need to know about custom punk rock pin design, materials, and manufacturing.

Nr. 5, Tongan Road,

Ostbezirk Xiaolan Town,

Zhongshan, Guangdong,

China

Urheberrecht © 2024, Zhongshan Peakeen Gifts Supply Chain Co., Ltd. Alle Rechte vorbehalten. Angetrieben von PeaKeen Datenschutzerklärung

Lassen Sie uns zusammenarbeiten, um Geschäftswachstum zu erzielen!