Pin del Equipo SWAT: Significado, Diseño y Guía de Personalización

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

Crear tu propia medalla requiere un poco de creatividad y unos pocos materiales.

Diseñe medallas personalizadas para su nuevo evento virtual, celebración especial o recuerdo personal. Usted es responsable del diseño de la medalla, el tamaño, la forma y el grabado interior.

Con opciones que van desde la selección de metales duraderos hasta la inclusión de grabados personalizados o cintas alegres, fabricar sus propias medallas es gratificante y adaptable.

En las páginas siguientes, le guiaremos paso a paso para ayudarle a crear una medalla digna de su causa.

Diseñar sus propias medallas ofrece una oportunidad que va más allá de la intención práctica de honrar los logros.

Puedes diseñar cosas que tengan impacto, resonancia y pegada. Estos custom designs será una representación directa de la misión y los valores de su evento u organización.

Las medallas personalizadas creativas llevan cualquier evento al siguiente nivel con diseños frescos y detalles significativos. No hay duda de que causan una gran impresión tanto en los destinatarios como en los participantes.

Cuando diseñas tus propias medallas, el grado de personalización que puedes alcanzar es algo que las medallas tradicionales no pueden ofrecer.

Tanto si se trata del material utilizado como de diseños detallados, podrá crear medallas que reflejen el espíritu de su evento y lo que está representando.

Por ejemplo, las medallas de metal son una opción atemporal para quienes buscan durabilidad. Pueden durar décadas y mantienen su elegancia con el paso del tiempo. Además, un diseño de doble cara aumenta realmente el factor único de la medalla.

Esto proporciona espacio adicional para incluir su logotipo, la fecha del evento u otras imágenes importantes.

Se pueden elegir cintas de distintos colores a juego con el diseño de la medallaLa medalla se puede personalizar para adaptarla a la marca o el tema de su evento. Al personalizar cada aspecto, se asegurará de que la medalla se adapte perfectamente a su visión creativa.

Las medallas personalizadas son la mejor manera de crear una representación física duradera de los grandes logros, convirtiendo cada medalla en una preciada recompensa para los ganadores.

Ya sea para una competición deportiva, un hito académico o un acto de reconocimiento corporativo, una medalla bien diseñada celebra el trabajo duro y la dedicación que han conducido al éxito.

Los grupos respetuosos con el medio ambiente pueden recurrir a materiales más respetuosos con la tierra, desde sustancias vegetales hasta papel de periódico reciclado. Estas decisiones están en consonancia con los objetivos de sostenibilidad, y el resultado final es un aspecto elegante y sofisticado.

Este concienzudo proceso sirve para reconocer el gran logro a la vez que proporciona información sobre la institución que concede el galardón.

Más allá de los premios Las medallas no son sólo recompensas: pueden ayudar a crear lazos comunitarios y generar sentimientos de inclusión.

Los diseños personalizados, sobre todo cuando se utilizan en actos comunitarios o en programas de formación de empleados y equipos, fomentan una fuerte identidad entre los participantes y refuerzan el espíritu empresarial.

Además, ayudan a mejorar la percepción general de un acontecimiento, lo que a su vez lo hace más atractivo para posibles patrocinadores. Solo en 2018, las marcas invirtieron $24.200 millones en patrocinios.

Si se centra en crear medallas únicas y creativas, conseguirá importantes patrocinios y aumentará enormemente el reconocimiento de su nombre. Las medallas personalizadas son una opción increíblemente económica, ya que muchas cuestan a partir de $0,80 cada una. Como ofrecen tanta flexibilidad, son ideales para eventos grandes y pequeños.

Diseñar una medalla única ofrece un divertido proyecto comunitario. Hay un puñado de cosas en las que deberías pensar antes de ponerte manos a la obra.

Cada decisión que tome repercutirá en el producto final, por lo que una planificación cuidadosa le garantizará una medalla que cumpla sus expectativas y aporte valor a su evento.

Veámoslo más de cerca, pieza por pieza.

El primer paso es saber lo que realmente debería representar su medalla. ¿Es para una competición atlética, un acto corporativo o el jubileo de una ciudad?

La finalidad prevista empezará a dictar cómo debe diseñarse la estructura, su tamaño e incluso qué tipo de materiales deben utilizarse.

Una medalla de finisher de un gran maratón puede necesitar un diseño grande y a prueba de bombas que encarne el espíritu de la carrera. En cambio, si se premia un hito corporativo, el galardón debe ser moderno y elegante.

A la hora de determinar el alcance de su iniciativa, tenga en cuenta cuántas personas recibirán la medalla. Es importante encontrar el equilibrio entre que todos los destinatarios reciban una medalla y que no haya de más.

Si se trata de un gran acontecimiento, como una carrera, calcule el número de participantes basándose en las tendencias de inscripción.

Tenga siempre en cuenta las inscripciones tardías o los aumentos inesperados de asistencia. Sean cuales sean tus objetivos, el objetivo es recompensar a todos los competidores sin crear una montaña de medallas sobrantes.

Su presupuesto tendrá una correlación directa con el tipo de medalla que pueda producir. Los precios suelen oscilar entre $0,80 y $6,90 por medalla. Esta variación se basa en los materiales, el tamaño y las características especiales, como el grabado personalizado o la colocación de lazos.

Los proveedores suelen tener cantidades mínimas que determinan el gasto final, así que tenlas en cuenta. Busca empresas como PeaKeen que te permitan hacer pedidos más pequeños con MOQ bajos. Esto proporciona una flexibilidad excepcional para los eventos más pequeños del mundo real o para aquellos con presupuestos restringidos.

Planificar con antelación también puede suponer un ahorro de millones de dólares. Si pide 2.000 o más medallas al menos dos meses antes de su evento, puede ahorrar $750. No deje pasar esta excelente oportunidad: ¡haga su pedido ahora!

Este nivel de previsión va más allá de su presupuesto y garantiza la entrega del proyecto a tiempo.

El calendario es fundamental para la participación del público. Dado que el diseño, la fabricación y el envío de las medallas pueden llevar semanas, asegúrese de trabajar con un margen de tiempo desde la fecha del evento. Así tendrás tiempo para hacer cambios en el diseño o resolver complicaciones inesperadas.

Si toma estas medidas con antelación, podrá estar seguro de que está completamente satisfecho con el producto final y evitará las prisas de última hora.

Diseñar una medalla personalizada es una experiencia inspiradora que brinda la oportunidad de crear algo memorable y único. Con herramientas fáciles de usar y recursos disponibles para todos los niveles de habilidad, nunca ha sido tan fácil convertir nuestras ideas en acción.

Aquí veremos los pasos más importantes para diseñar una medalla impresionante.

El primer paso es pensar qué simboliza la medalla. Desde un reto deportivo a un premio por un largo servicio o un hito personal, cada diseño debe hablar de su uso previsto.

Le ayudaremos a empezar con una lluvia de ideas sobre temas, símbolos o imágenes relacionados con el acontecimiento o logro. Por ejemplo, una medalla para una carrera probablemente incluiría algún tipo de imagen de una pista o, al menos, la silueta de un corredor.

Alternativamente, podemos hojear pinterestcon más de 500 plantillas de stock y miles de elementos de diseño. Estas plantillas ofrecen un aspecto único y profesional, desde diseños tradicionales a otros más contemporáneos. Son geniales para establecer la forma básica y la sensación de nuestro diseño.

La forma y el tamaño de la medalla influyen mucho en su vistosidad. Aunque las formas comunes, como círculos, cuadrados y rectángulos, son las más versátiles, las medallas personalizadas, como estrellas, escudos o una mascota específica, aportan aún más personalidad.

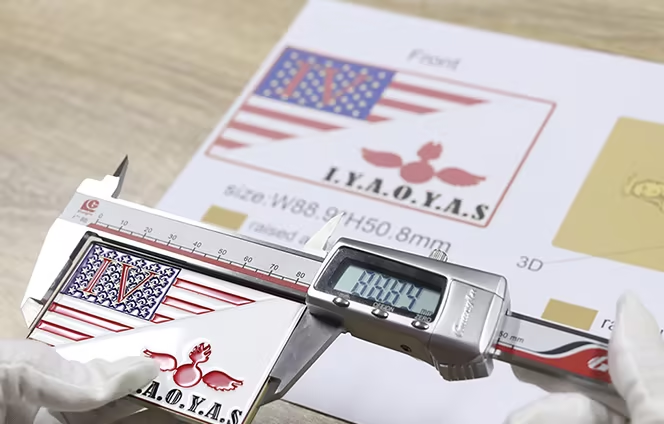

El tamaño típico oscila entre 5 y 10 cm de diámetro. Esto varía en función del nivel de detalle que queramos incorporar.

Las decisiones sobre el material determinan la experiencia estética y táctil de la medalla. Puede elegir entre aleación de zinc, latón o acero inoxidable, todos ellos increíblemente duraderos y con una superficie brillante.

Podemos mejorar la medalla eligiendo dos colores cualesquiera que tengan el mismo acabado para crear contraste. Por ejemplo, si combinamos oro antiguo con plata obtendremos un bonito aspecto multitonal.

Personalizaciones como letras, logotipos o ilustraciones exclusivas lo hacen suyo. El sencillo sistema de PeaKeen hace que sea fácil cargar nuestros diseños personalizados o trabajar directamente con los diseñadores internos para obtener orientación y experiencia profesional.

Las letras opcionales pueden añadir más personalización a la medalla, con hasta 30 caracteres incluidos de forma gratuita.

Antes de la producción, vamos a ir y venir para asegurarse de que está 100% satisfecho con el diseño. Su satisfacción es la máxima prioridad de PeaKeen.

Le prometemos que siempre recibirá un trabajo de calidad, como demuestran los miles de fantásticos comentarios de nuestros clientes.

Tanto si diseña su primera medalla como su trigésimo primera, elegir el mejor material es una decisión importante. Aunque cada opción presenta ventajas distintas, todas sirven para algo y se adaptan a todas las necesidades, gustos y presupuestos. Conocer las diferencias de cualidades entre cada material base nos ayuda a elegir sabiamente.

Esta compatibilidad con objetivos táctiles y visuales no hace sino ampliar nuestras opciones creativas.

Las medallas de metal son una opción tradicional y popular por su calidad duradera y su aspecto clásico. Son perfectas para quienes buscan un recuerdo tangible que perdure durante generaciones. Tradicionalmente, los metales más utilizados han sido el oro, la plata y el bronce.

Una medalla de oro contiene al menos 6 gramos de oro. Las medallas de plata, por ejemplo, están compuestas de al menos 92,5% de plata, lo que garantiza su alta calidad. El bronce, la opción de medalla más económica, ofrece un aspecto clásico con una apariencia fuerte y brillante.

Las medallas de metal suelen ser la opción menos cara, sobre todo cuando se hacen pedidos al por mayor. Por ejemplo, el coste de comprar 500 medallas de tamaño medio oscilará entre $2,00 y $2,75 cada una.

Si sigue trabajando con una tirada más corta, piense en las medallas insertables. Tienen un anillo exterior de metal distintivo con un centro grabado y personalizable y ahorrar dinero cuesta aproximadamente $3 cada uno por la misma cantidad.

Para quienes deseen aventurarse más allá de las opciones clásicas, materiales alternativos como la madera ofrecen una alternativa única y sostenible.

Las medallas de madera se fabrican con materiales vegetales como la madera reciclada sostenible, lo que las hace increíblemente sostenibles. Pueden personalizarse con complejos grabados, lo que hace que cada pieza sea única.

La sostenibilidad es uno de los principales objetivos de la fabricación de medallas en general. Las medallas de madera son únicas por su naturaleza respetuosa con el medio ambiente y su amplia versatilidad.

Para quienes disponen de un presupuesto más reducido, las medallas de metal duro que aún se encargan en masa son una opción asequible. Cómo equilibrar en gran medida la sostenibilidad con la asequibilidad depende de la intención y el tamaño del proyecto.

Al producir medallas personalizablesComprender los distintos factores de coste es crucial para evitar gastos innecesarios. Desde la calidad artesanal de los materiales utilizados hasta los diseños innovadores en el proceso de producción, todas estas decisiones afectan significativamente al medalla final coste. Esto es lo que hay que tener en cuenta a la hora de calcular el coste de una medalla personalizada.

Los materiales que seleccionamos son el principal factor que influye en los costes. Los materiales más comunes son la aleación de zinc, el latón o el aluminio.con ventajas y costes distintos. Por ejemplo, la aleación de zinc es resistente y asequible, por lo que suele utilizarse para pedidos de grandes cantidades.

El latón confiere a sus medallas un acabado de mayor calidad, pero encarece el precio. Para proyectos con presupuestos más ajustados, el aluminio ofrece una opción más ligera y rentable. Los precios pueden oscilar entre US$0,80 y US$6,90 por medalla, según el material utilizado y la cantidad pedida.

Los diseños de medallas que incluyen inserciones impresas suelen ser más baratos. Este es el caso, en particular, de los pedidos inferiores a 150 unidades en comparación con las alternativas de metal.

Los costes de utillaje, que sólo se producen una vez, tienen un impacto dramático en el presupuesto. Se necesitan moldes y troqueles especializados para cortar y estampar los diseños en las medallas. Aunque el coste inicial pueda parecer caro, resulta más rentable con cantidades mayores.

Pedir 5.000 medallas reduce mucho el coste por medalla. En lugar de gastar $3,25 USD por 500 medallas, sólo gastará $1,90 USD por el pedido de mayor volumen. Con una planificación adecuada, como hacer el pedido con dos meses de antelación, puede ahorrar cientos de euros en pedidos al por mayor, a veces hasta $750 USD.

Planificar con antelación nos da flexibilidad para probar las herramientas a fondo antes de la producción y minimizar el tiempo perdido por los retrasos.

Depende de la medalla, el proceso de producción influye mucho en el coste. Estos métodos pueden incluir la fundición a presión, el estampado y el corte por láser. La fundición a presión permite diseños más complejos, pero es más cara debido al minucioso proceso de troquelado.

El estampado es económico para diseños más sencillosmientras que el corte por láser ofrece un alto nivel de detalle pero suele necesitar procesos de acabado adicionales. Ya sea a través de un diseñador o directamente, los pedidos al por mayor reducen significativamente los costes al repartir los gastos fijos entre un mayor número de unidades.

Como regla general, un diseño muy intrincado suele aumentar los costes por la necesidad de moldes complicados y trabajo manual añadido.

Los añadidos a su diseño, como el esmalte multicolor, las formas personalizadas o los diseños en capas, requieren más pasos de producción.

Una combinación incorrecta de colores y materiales puede resultar desafortunada, como utilizar una cinta muy ancha con una medalla pequeña. Encontrar el equilibrio adecuado entre diseño y funcionalidad puede ayudarle a maximizar la estética sin comprometer la rentabilidad.

A la hora de producir medallas personalizables, hay muchos factores que influyen en el tiempo que transcurre desde el diseño de la medalla hasta su entrega. Si conoce estos elementos, podrá establecer expectativas realistas para sus interlocutores y garantizar una experiencia positiva con medallas personalizadas de calidad.

La fase de diseño suele ser la de mayor colaboración y requiere varias rondas de revisión y ajustes para recibir la aprobación final. Una vez que les proporcione su boceto conceptual, el fabricante se pondrá a trabajar de inmediato. Pueden producir un renderizado digital inicial o un prototipo rápido con impresión 3D, fundición en arena o mecanizado CNC.

Estos prototipos actúan como piezas de prueba para garantizar que el ajuste y la función del diseño son los adecuados. Le rogamos que nos comunique si necesita algún cambio y lo revisaremos según sea necesario. Dependiendo de su complejidad, este paso puede añadir varios días o incluso semanas al plazo de producción de la medalla.

Por ejemplo, si incluye diseños muy detallados o emblemas exclusivos, la elaboración puede requerir más cuidado. Las aprobaciones rápidas por tu parte pueden ayudar a mitigar este tiempo y tener un gran efecto en el calendario general.

| Esmalte blando | Fill the paint colour into the products. The surface is linear. |

| Esmalte duro | En la fase posterior se pule la superficie para conseguir el efecto esmaltado. La superficie queda lisa. |

| Impresión UV | Print a pattern on the surface(Suitable for more complex pattern colours or colour gradients) |

| Epoxi | Se añade una capa de cola transparente a la superficie del producto para protegerlo |

| Resplandor | Al absorber la luz, la noche puede brillar |

Transparent Colours | El color es transparente y se puede ver el fondo |

| Recorte | Recorta el producto y muévelo para conseguir un efecto hueco |

| Dos tonos | The same product is electroplated in two colours |

| 3D/2D | En forma de arco o multicapa / el producto sólo tiene dos capas cóncavas y convexas |

| Recubrimiento metálico | The process of attaching a layer of the metal film to the surface of metal or other material parts by electrolysis. It can prevent corrosion, improve wear resistance, conductivity, and reflective properties, and enhance appearance. And make medals shiny gold in the sun, you can choose shiny gold silver or antique gold silver. |

| Vidrieras | Cut out part of the pin and fill in the transparent colour |

| Gema | Set your pin with artificial diamonds (diamonds are available in a variety of colours) |

| Bisagra | El pasador de dos capas puede diseñarse para abrirse y cerrarse o girar como una puerta |

Insert | Custom insert medals, insert your branding or design on blank medals with your logo |

Una vez aprobado el diseño, comienza el proceso de producción. Este paso incluiría cualquier proceso, como fundición, troquelado o mecanizado CNC, para dar forma a las medallas. A continuación se realiza el tratamiento posterior a la fundición, en el que se recorta el material sobrante, se mecanizan los orificios para las correas y se dan los toques finales, como la galvanoplastia o el pulido.

Cada paso del proceso exige la máxima precisión y, por desgracia, tiempo. Por ejemplo, para un pedido muy grande de 5.000 medallas o más, es posible que se tarde una semana más en producirlas en función de las normas de calidad que tienen que mantener.

Los fabricantes tienden a realizar controles de calidad en los primeros lotes producidos antes de pasar a la producción total. Para proyectos de alto perfil, como las medallas olímpicas, Otras medidas pueden incluir el uso de materiales sostenibles, la garantía de un abastecimiento justo y el mantenimiento de la transparencia en la cadena de suministro. Estos factores dan prioridad a las consideraciones éticas, pero pueden alargar aún más los plazos.

Una vez finalizada la fabricación, el envío y la distribución son la última etapa del proceso. Los plazos de entrega dependen de su ubicación y de la opción de envío seleccionada. Elegir el envío acelerado de medallas puede reducir drásticamente el tiempo de espera, pero puede aumentar significativamente el precio.

Si lo planifica con antelación, ahorrará mucho dinero. Si encarga 2000 medallas con dos meses de antelación, ahorrará mucho dinero. te costará un estimado de $750. Cuando usted planificar con antelación, no incurrirá en gastos de envío urgente.

Debe tener en cuenta en su calendario los retrasos inesperados, como el despacho de aduanas para los envíos internacionales.

Saber qué esperar al hacer un pedido medallas personalizadas hace que todo el proceso sea mucho más fluido.

Esta experiencia le garantiza que recibirá un producto de gran calidad, como medallas personalizadas, exactamente cuando lo necesite. A continuación le mostramos algunos pasos importantes del proceso de diseño de medallas.

El primer paso suele ser una llamada introductoria en la que podemos hablar de su visión y sus necesidades.

Es el momento de decidir detalles importantes como el tamaño, el material, la forma y el acabado de la medalla. Por ejemplo, puede decidir que prefiere un acabado metálico brillante frente a un material reciclado de madera o acrílico.

Duraderas, muy pulidas y tradicionales en grandes eventos, las medallas de metal se encuentran entre los materiales más populares. Si buscas una solución más rápida, las opciones de madera o acrílico fabricadas aquí mismo, en nuestra tienda, están disponibles en tan solo 1-2 semanas.

Si nos quedáramos con el diseño ganador, tendríamos que enviar el material gráfico del mismo. Tanto si envía un logotipo básico como un diseño más complejo, Cuanto más claras y detalladas sean sus propuestas, menos revisiones necesitarán en el futuro.

Tenga en cuenta que la cantidad mínima para la mayoría de las medallas de carreras es de unas 100 medallas. Si tiene en mente un evento de mayor envergadura, cuanto antes haga su pedido, más ahorrará. Por ejemplo: Si encarga 2.000 medallas con dos meses de antelación, ahorrará $750.

Tener una buena comunicación durante el proceso de creación es muy importante. Dado que la mayoría de las medallas personalizadas se fabrican en el extranjero, los plazos de entrega suelen ser de 1 a 10 semanas, con el tiempo necesario para la producción y el envío. La producción por nuestra parte requiere de 3 a 4 semanas, dependiendo de la complejidad.

| Tipo de envío | Hora de referencia |

| DDP por mar | 30 - 35 días |

| DDP por aire | 15 - 18 días |

| Express | 3 - 7 días |

| Por carretera | 25 - 30 días |

| Por ferrocarril | 25 - 30 días |

La comunicación constante con el fabricante le garantiza que siempre estará informado y le deja tiempo suficiente para solucionar cualquier problema. Las medallas de metal suelen costar entre $2 y $2,75 cada una cuando se piden 500 de un tamaño estándar.

Si tiene dudas sobre sus cantidades, empiece por un 10% DNS (No arrancó) media. Esto es especialmente útil para eventos de participación masiva como nuestro TRR. Esto le ayudará a asegurarse de que tiene la cantidad justa de medallas, ni demasiadas ni demasiado pocas.

Justo antes del envío, realizamos varias controles de calidad en las medallas para asegurarse de que se ajustan estrictamente a su pedido. Este sencillo paso evita confusiones innecesarias, sobre todo cuando se piden grandes cantidades.

Comprobar aspectos como la calidad del grabado, los acabados superficiales y el arte en general garantiza el éxito del producto final.

Es un divertido proyecto práctico que combina arte, habilidad y misión. Ya sea para un evento escolar, una competición deportiva o un hito personal, la creación de medallas personalizables ofrece oportunidades para el desarrollo de habilidades, la conexión familiar e incluso el enriquecimiento educativo. Para que tu proyecto sea atractivo y tenga impacto, aquí tienes cinco aspectos clave que debes tener en cuenta.

Empiece con los diseños más sencillos y las implementaciones más básicas. Este método ayuda a garantizar que el proyecto se mantiene dentro de lo manejable, ideal para principiantes o participantes más jóvenes.

Crear un diseño de medalla de dos caras ofrece oportunidades artísticas dinámicas. Puede personalizar las medallas añadiendo su logotipo en una cara y un mensaje personalizado o una fecha en la otra. No tienen nada de malo, y utilizar formas básicas como círculos o estrellas como plantillas facilita mucho este proceso.

Trabajar con un proveedor de confianza, como PeaKeen, le garantiza el acceso a los mejores materiales. Sus conocimientos prácticos le ayudarán a transformar sus mejores ideas en proyectos de éxito.

Probar distintos métodos y materiales te ayudará a descubrir qué es lo que mejor funciona. Trabaja con diferentes pinturas, pinceles, herramientas, técnicas mixtas, adornos, etc. para crear el estilo y el ambiente deseados.

Todo lo que conlleva esa medalla, desde cortar, pintar y enhebrar cintas, ¡hace que la creación del producto final sea especial! Esta actividad práctica fomenta aún más la motricidad fina, creando un doble valor para los niños.

Los avances tecnológicos han hecho que las cintas sublimadas sean más rentables, por lo que podrá añadir diseños coloridos y duraderos con menos esfuerzo. No pase por alto la importancia de hacer algunas pruebas para asegurarse de que sus medallas finales tienen el aspecto que tenía en mente.

Solicitar la opinión de otras personas puede elevar sustancialmente la calidad de su proyecto. Familiares, amigos e incluso antiguos o actuales compañeros de equipo pueden aportar ideas para progresar.

Mientras fabrican medallas juntos, entablarán relaciones, compartirán un montón de diversión e inspirarán toda una vida de aventuras. Incorpora los comentarios de los malos actores para que te ayuden a reforzar tus diseños, asegurándote de que encajan con el objetivo final o el tema del evento.

Este proceso colectivo iterativo siempre produce un resultado más nítido y profundo.

La creatividad es sin duda la clave del éxito de un proyecto, especialmente cuando se diseña medallas personalizadaspero la seguridad debe ser siempre lo primero. Si va a haber participantes jóvenes, planifique materiales y actividades que sean amables y apropiados para los niños.

Al diseñar sus propias medallas personalizables, puede adaptar su premio a algo que tenga un verdadero significado personal para sus participantes.

Es ideal para reconocer logros, marcar un evento o dar un toque único a las presentaciones de premios con una artesanía de calidad. Únicas y personalizadas, las medallas personalizadas dejan un impacto memorable.

Las opciones más populares de medallas personalizadas incluyen aleación de zinc, latón y acero inoxidable. Para una sensación fresca y contemporánea, puede considerar acabados esmaltados o incluso PVC blando.

Comprender cómo influye cada material en la durabilidad, el peso y el coste es esencial para seleccionar medallas personalizadas de calidad que se ajusten a su presupuesto.

El precio de las medallas personalizadas puede aumentar considerablemente en función de factores como el tamaño, el material y la complejidad del diseño de la medalla.

Los precios de venta al público suelen ser a partir de $2-$10 por medalla para pedidos de grandes cantidades, mientras que añadir personalizaciones como grabados o chapados especiales puede elevar los costes.

Los plazos de producción de las medallas personalizadas varían en función del diseño y la cantidad. Por lo general, desde la aprobación del diseño, hay un plazo de 3 a 6 semanas antes de que lo tengan en casa.

Pedidos urgentes para las medallas personalizadas de calidad a veces se pueden acomodar, pero probablemente incurrirá en un cargo adicional.

Características a incluir como el título del acontecimiento, fecha y cualquier elemento de marca como un logotipo personalizado o una mascota relevante.

Elija un tipo de letra sencillo y fácil de leer. Desde medallas deportivas a medallas de premios corporativos o logros personales, asegúrese de que el diseño de su medalla personalizada se ajusta al propósito general de la medalla.

Aunque algunos fabricantes de medallas personalizables ofrecen cantidades mínimas de pedido reducidas, los costes por medalla suelen ser más elevados para tiradas más cortas. Consulte siempre al proveedor de sus materiales antes de iniciar un proyecto.

En cuanto detecte algún problema, como roturas o errores, en sus medallas personalizadas, póngase en contacto con el fabricante de inmediato.

La mayoría de las organizaciones ofrecen revisiones gratuitas o garantías de devolución del dinero de acuerdo con sus directrices. Pruebe con cuidado y asegúrese de que todos los materiales de diseño de medallas son correctos antes de empezar la producción.

Table of Contents A SWAT team pin is a specialized insignia worn by SWAT personnel to symbolize role, qualification, and

Table of Contents This guide covers everything you need to know about custom punk rock pin design, materials, and manufacturing.

No. 5, Tongan Road,

Distrito Este de Xiaolan Town,

Zhongshan, Guangdong,

China

Derechos de autor © 2024, Zhongshan Peakeen Gifts Supply Chain Co., Ltd. Todos los derechos reservados. Desarrollado por PeaKeen Política de privacidad

Trabajemos juntos para lograr el crecimiento empresarial!.