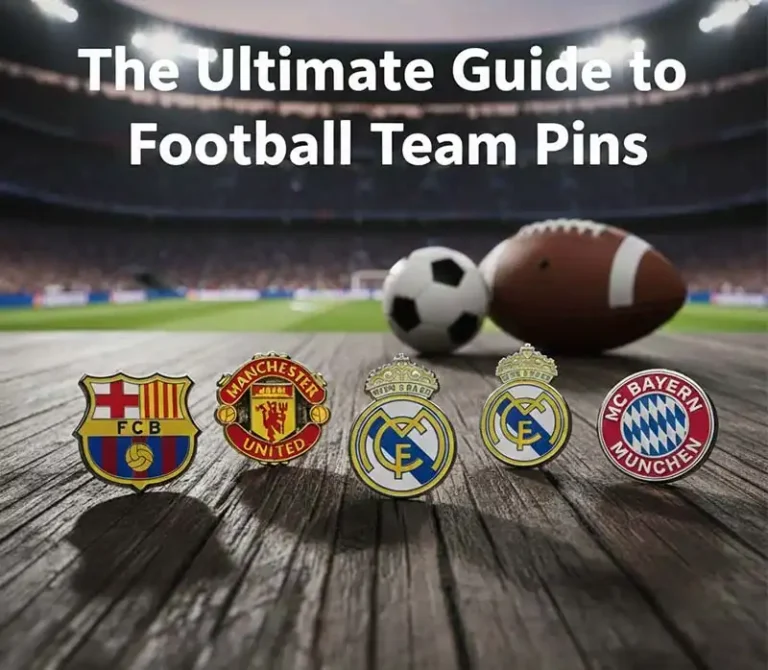

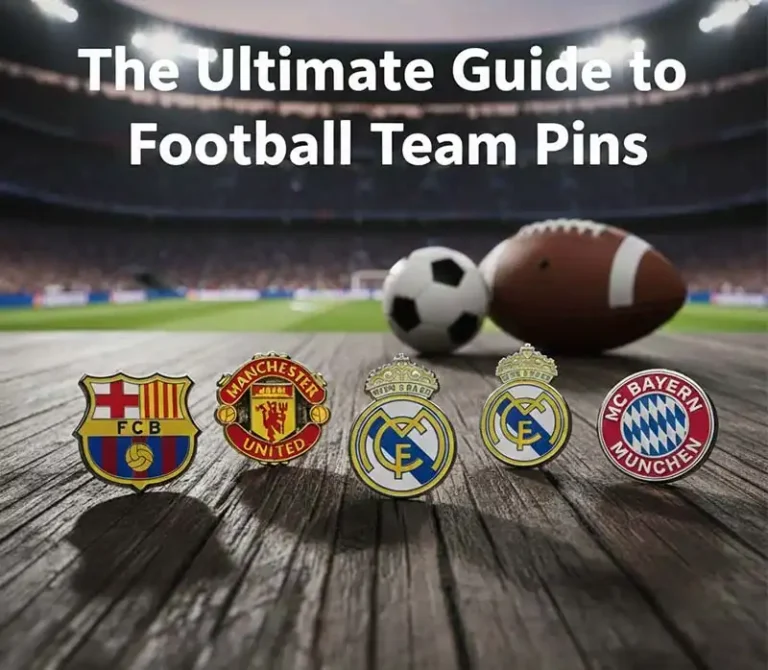

Le guide ultime des pins des équipes de football

Table of Contents What Are Football Team Pins? Football team pins are small decorative items designed to represent football teams,

Badges de police vierges sont un outil unique et polyvalent conçu pour la personnalisation, la formation ou la collection. Ces badges constituent une merveilleuse toile pour l'expression artistique.

Généralement fabriqués à partir d'éléments robustes tels que le métal ou le plastique, ils peuvent être facilement gravés ou imprimés avec des logos ou des lettres personnalisés. Souvent utilisés par les services de police, les entreprises de sécurité ou les amateurs, ils sont très polyvalents et permettent de réaliser des badges personnalisés ou des imitations.

Qu'ils soient utilisés dans le cadre d'une fonction officielle ou comme objets de collection personnels, les badges vierges constituent une base fonctionnelle idéale pour de nombreuses utilisations.

Un badge de police vierge est un insigne générique par défaut conçu pour être personnalisé, ce qui lui confère une grande polyvalence dans la plupart des contextes d'application de la loi. Ces badges sont souvent fabriqués dans des matériaux durs tels que le métal ou le plastique ABS. Ils ont tendance à prendre la forme traditionnelle d'un bouclier, d'une étoile ou d'un cercle, ce qui permet aux services de les personnaliser en fonction de leurs besoins.

Par exemple, une page blanche badge de police peuvent être gravés ou marqués de numéros de série spécifiques, d'insignes ou d'autres symboles pour désigner les différents grades ou juridictions.

Dans le cadre de la formation, les badges vierges sont des ressources indispensables. Ils permettent aux recrues de développer une identité et un professionnalisme dans leur rôle, sans pour autant leur conférer une autorité officielle avant qu'elles ne soient prêtes. Tout comme lors des funérailles, lors des cérémonies, ils sont un symbole d'honneur et de reconnaissance.

Les services de police les utilisent également dans le cadre de programmes de sensibilisation et d'événements communautaires, où ces badges de police personnalisés permettent d'établir des liens et des relations positives.

Abordable badges de police vierges sont le choix économique parfait pour les services qui cherchent à économiser de l'argent tout en promouvant une apparence professionnelle. Contrairement aux conceptions entièrement personnalisées qui peuvent nécessiter beaucoup de temps pour la planification, le développement et la production, les badges vierges minimisent le coût d'entrée.

Par exemple, nombre d'entre eux sont gratuits ou ont des frais d'expédition peu élevés, ce qui les rend faciles à utiliser et abordables. Leur flexibilité est peut-être leur plus grand atout. Les badges de police vierges s'adaptent facilement à tous les grades et à tous les rôles, ce qui permet à votre uniforme de rester impeccable grâce à un format unique - et non à des modèles multiples - dans l'ensemble du service.

Ils excellent dans la personnalisation, permettant aux services d'ajouter un texte spécifique pour des événements tels que la sensibilisation de la communauté ou les cérémonies commémoratives en l'honneur des officiers tombés au combat. Ces badges sont parfaits pour les missions de courte durée ou les opérations spéciales, car ils offrent un modèle de badge de saut personnalisable qui peut être adapté à des missions spécifiques.

Le processus de création de badges de police vierges implique de choisir des matériaux, chacun d'entre eux étant spécifiquement conçu pour remplir des fonctions uniques. Les matériaux les plus prisés sont le métal, le plastique et l'émail.

Badges en métalLes badges en plastique, généralement en laiton ou en alliage de zinc, constituent une excellente base durable et sont généralement choisis pour leur longévité. Les badges en plastique, généralement en styrène, offrent une option vivante et légère. Ils ont tendance à avoir des finitions argentées ou dorées qui leur donnent un aspect très réel.

L'émail est souvent ajouté pour les détails décoratifs, ce qui rend l'insigne encore plus impressionnant. Le processus de fabrication innovant fait appel à des méthodes de précision pour garantir une qualité optimale.

Les badges en métal sont moulés sous pression ou estampés, puis traités par galvanoplastie afin d'obtenir la finition souhaitée. Les badges en plastique sont fabriqués par moulage par injection, ce qui permet d'obtenir des formes très régulières, puis ils sont recouverts d'un revêtement pour résister aux rayures et à la décoloration. Chaque badge est muni d'un clip de sécurité pour les enfants, ce qui permet de le porter en toute sécurité.

Pour être efficaces, les drapeaux éoliens doivent être durables et résister aux intempéries. Les écussons en métal indiquent un gardien de l'environnement qui résiste à l'épreuve du temps, souvent utilisé à l'extérieur.

Les badges en plastique sont plus légers, mais ils sont conçus pour résister à des conditions plus tempérées et plus douces. L'émail ajoute une couche de protection naturelle qui empêche les marques et les éraflures. Par exemple, les badges de type bouclier ou Lone Star sont conçus pour durer, qu'ils soient utilisés par application de la loi ou des collectionneurs.

La fabrication et le déploiement de répliques de badges de police est une tapisserie tissée de fils juridiques et éthiques. Aux États-Unis, des règlements tels que la section 17-2.1 du code pénal de 1961 prévoient des exceptions pour les badges utilisés dans des productions théâtrales ou cinématographiques. C'est le cas à moins qu'ils n'aient directement l'intention d'induire le public en erreur.

L'utilisation abusive à des fins terroristes, comme le fait de se faire passer pour les forces de l'ordre dans le cadre d'une intervention d'urgence, est un délit passible de sanctions sévères. À New York, il s'agit d'un délit de classe B passible d'une amende de $2 000 ou d'une peine d'emprisonnement de six mois. En l'absence de tout contrôle, des considérations éthiques entrent en jeu lorsque les badges sont reproduits ou affichés sans autorisation.

En Californie, l'association des officiers de police de Glendale a placé des boîtiers sur ses badges commémoratifs afin d'éviter les détournements. Une tenue cohérente et adéquate des registres et la transparence de la politique de l'agence sont essentielles pour responsabiliser les forces de l'ordre et gagner la confiance du public.

Les insignes de police sont un excellent exemple de cette variation, car ils présentent des caractéristiques régionales distinctes qui reflètent la culture, les traditions et les cadres juridiques locaux. Aux États-Unis, les insignes des forces de l'ordre sont souvent ornés de symboles droits tels que le drapeau américain, un bouclier ou des armoiries, ou encore la balance de la justice. Ces motifs célèbrent fortement les valeurs de service et de justice, et utilisent souvent différents styles d'insignes de police pour véhiculer leur signification.

Les conceptions varient d'un département à l'autre et même d'un État à l'autre, la construction et les styles étant très différents. Les zones urbaines sont plus susceptibles de privilégier l'esthétique moderne et l'attrait industriel, tandis que les communautés rurales préfèrent l'esthétique traditionnelle. À New York, les détails sont un point fort, les badges présentant un travail manuel élaboré et des motifs complexes.

En revanche, les départements du Texas comportent presque toujours des emblèmes de l'État, comme la Lone Star. À l'échelle mondiale, les différences sont encore plus marquées. Au Royaume-Uni, les insignes de police sont souvent ornés d'une couronne en signe de monarchie, tandis que les insignes français s'inspirent fortement de l'héraldique.

Chaque élément, de la forme de l'insigne à l'emblème du shérif, reflète une histoire fondée sur l'intersection de la région et de l'identité, symbolisant l'engagement en faveur de la protection et du service.

La conception d'un badge de police personnalisé est l'occasion idéale d'exprimer son individualité tout en conservant un air de professionnalisme. Les outils de conception numérique permettent plus que jamais de le faire soi-même, en jouant avec les formes, les couleurs et la typographie.

Ces plateformes proposent généralement des modèles pour différents types de badges, du bouclier traditionnel à l'étoile, ce qui vous offre de nombreuses possibilités de création. Pour commencer, choisissez un matériau durable, capable de résister aux conditions auxquelles il sera confronté.

Ensuite, choisissez des touches décoratives telles que le plaquage d'or ou d'argent pour aller encore plus loin dans la beauté. Les logos des services, les noms des agents, les numéros de badge sont autant de détails qui ajoutent à la personnalisation et au lien étroit avec votre rôle spécifique.

Pour assurer la conformité, vérifiez les réglementations et directives locales relatives à la taille des badges et aux symboles, insignes, etc. Veillez à ce qu'il soit clair et facile à lire pour que votre badge ait un aspect net et soigné.

Ce design personnalisable côtoie une fonction intelligente, donnant à votre badge un aspect totalement unique.

Plus qu'un outil d'identification, un badge de police personnalisé est l'un des investissements les plus importants en matière de professionnalisme et de distinction que porteront vos agents. Ces badges de police personnalisés comportent souvent des décorations élaborées, telles que des sceaux de service de police et des formes complexes et spéciales. Cela permet de créer une identité de marque immédiate et puissante et d'améliorer la façon dont le public perçoit ces agents.

Par exemple, la Commission ABLE de l'Oklahoma utilise efficacement son badge pour mettre en valeur la profondeur historique de son département. Les badges personnalisés favorisent la confiance au sein de la communauté en agissant comme une représentation visuelle du dévouement et des services rendus par le service à la population.

Lorsqu'un agent porte un insigne, créé avec réflexion et art, il en tire de la fierté et, par conséquent, le meilleur dans l'action. Cette fierté augmente le moral et renforce la solidarité, comme nous l'a montré le service de police de Camden. D'autres aspects fonctionnels, tels que les dispositifs de sécurité intégrés, ajoutent une fonctionnalité considérable et préservent l'authenticité du badge.

Pour connaître le prix des badges de police vierges, il faut tenir compte de plusieurs facteurs. Le choix du matériau est un facteur important. Les badges dorés, argentés ou bicolores coûtent tous des sommes différentes. Badges d'orpar exemple, sont généralement d'un coût prohibitif en raison de leur longue durée de vie et de considérations esthétiques.

La quantité est le troisième facteur important. Les remises s'appliquent aux commandes de 50 badges ou plus, les économies pouvant atteindre 20% pour les commandes de plus de 100 badges. Il n'y a pas de montant minimum pour la plupart des commandes, même si vous ne commandez qu'un seul badge.

Les badges de police vierges sont de puissants symboles de confiance, d'autorité et d'engagement. Une formation adéquate à leur utilisation et à leur affichage est essentielle pour s'assurer qu'ils sont traités avec le respect qu'ils méritent.

Nous savons qu'une utilisation abusive ou une fausse déclaration peut avoir des effets néfastes, qu'il s'agisse de semer la confusion dans l'esprit du public ou d'éroder la confiance. Les ministères doivent mettre en œuvre des règles claires concernant badge la distribution et l'utilisation, en veillant à ce que les zones de conservation ou l'utilisation soient conformes aux lois locales, nationales et fédérales.

Un insigne représente bien plus qu'un nom sur une porte. Il reflète un désir profond de protéger les autres, une attitude conférée par ceux qui portent l'uniforme avec fierté à PeaKeen. L'utilisation responsable va au-delà de la protection de la sécurité publique ; elle protège la profession de policier. application de la loi également.

Un badge de police vierge en particulier se distingue par le fait qu'il s'agit d'un outil rare et polyvalent, doté d'une valeur à la fois pratique et symbolique. Leur polyvalence les rend parfaits pour les collectionneurs, les accessoires de film ou une utilisation professionnelle personnalisée. Le choix d'un matériau et d'un modèle appropriés garantit la durabilité et un aspect soigné, tandis que les options de personnalisation vous permettent de créer quelque chose d'unique et de significatif. Le respect des paramètres juridiques garantit une utilisation responsable et empêche l'exploitation de la technologie.

Vous souhaitez reconnaître un rôle ou célébrer un anniversaire ? L'achat d'un badge vierge dans lequel investir soutient la créativité et l'innovation des jeunes dans un but social, tout en enrichissant votre propre collection. Les possibilités sont illimitées lorsque l'on coupe les coins ronds, que l'on commercialise tout et que l'on lie l'art au dollar de l'homme blanc. Renseignez-vous sur les options qui s'offrent à vous et créez un badge qui montre au monde ce que vous voulez être et ce que vous défendez ! Vous souhaitez en savoir plus sur les techniques de défense du budget ? Rejoignez-nous et créez un badge qui nous fera réagir.

Un badge de police vierge, souvent considéré comme une toile blanche, est un badge de police non gravé qui offre aux organisations la possibilité de le personnaliser avec leur logo, leur nom ou leur insigne unique, reflétant ainsi leur style et leur identité spécifiques.

Oui, mais trop souvent des restrictions leur sont imposées. De nombreux vendeurs demandent une preuve d'autorisation, non seulement pour des raisons de responsabilité juridique, mais aussi pour garantir la conformité avec les styles de badges des forces de l'ordre. Consultez toujours votre législation locale avant d'acheter.

Les badges en plastique vierges sont souvent fabriqués à partir de métaux de base durables tels que le laiton, le zinc ou le nickel, tandis que d'autres choisissent la fonte d'aluminium ou l'acier inoxydable, plus fins et de moindre calibre, pour économiser de l'argent sur les modèles de badges destinés aux forces de l'ordre.

La personnalisation permet aux agences d'ajouter les nouveaux identifiants des juridictions, d'accroître le professionnalisme et d'améliorer l'authenticité de ces badges des forces de l'ordre. Elle peut servir à exprimer la fierté d'une région ou d'un département par le biais de différents styles de badges de police.

Les lois sur la propriété diffèrent d'un État à l'autre. Il est légal pour les collectionneurs légitimes ou les personnes ayant une fonction officielle, mais il n'est pas légal d'abuser de la police ou de se faire passer pour elle.

L'utilisation abusive d'un badge de police en plastique vierge entraînera des sanctions civiles et/ou pénales et portera atteinte à la confiance et à la bonne volonté du public. Nous vous rappelons qu'il convient d'utiliser les modèles de badges des forces de l'ordre de manière responsable et légale à tout moment.

Table of Contents What Are Football Team Pins? Football team pins are small decorative items designed to represent football teams,

Table of Contents What is a Flower Pin? Flower pins, often called flower lapel pins or boutonnieres, serve as ornamental

No. 5, Tongan Road,

District Est de la ville de Xiaolan,

Zhongshan, Guangdong,

Chine

Droits d’auteur © 2024, Zhongshan Peakeen Gifts Supply Chain Co., Ltd. Tous droits réservés. Propulsé par PeaKeen Politique de confidentialité

Travaillons ensemble à la croissance des entreprises!

Travaillons ensemble à la croissance des entreprises!

10% Off